- Home

- Research

- Education & Outreach

- Facilities

- Industry

NSF Highlights

Rapid Fabrication of Nanoparticles with Excellent Size Control

Self-assembling polymer nanoparticles that are driven by coordination interactions between a boron functionality in one polymer chain and the imine functionality in the neighboring polymer chain has been demonstrated by Thayumanavan, of the Center for Hierarchical Manufacturing at UMass Amherst. This rapid and convenient method has been developed in collaboration with Dai (Xiamen University, China). In addition to the simple preparation of these nanoparticles, these particles have also been shown to be thermally reversible, where the fidelity of the nanoparticle survives thermal cycling.

Self-assembling polymer nanoparticles that are driven by coordination interactions between a boron functionality in one polymer chain and the imine functionality in the neighboring polymer chain has been demonstrated by Thayumanavan, of the Center for Hierarchical Manufacturing at UMass Amherst. This rapid and convenient method has been developed in collaboration with Dai (Xiamen University, China). In addition to the simple preparation of these nanoparticles, these particles have also been shown to be thermally reversible, where the fidelity of the nanoparticle survives thermal cycling.

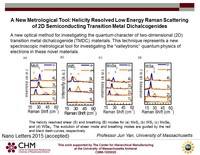

A New Metrological Tool: Helicity Resolved Low Energy Raman Scattering of 2D Semiconducting Transition Metal Dichalcogenides

A new optical method for investigating the quantum character of two-dimensional (2D) transition metal dichalcogenide (TMDC) materials. This technique represents a new spectroscopic metrological tool for investigating the “valleytronic” quantum physics of electrons in these novel materials.

A new optical method for investigating the quantum character of two-dimensional (2D) transition metal dichalcogenide (TMDC) materials. This technique represents a new spectroscopic metrological tool for investigating the “valleytronic” quantum physics of electrons in these novel materials.

$25M Advanced Roll-to-Roll Manufacturing Demonstration Facility to Open as Part of UMass Center for Personalized Health Monitoring

The $25,000,000 Center for Advanced Roll-to-Roll Manufacturing is an open access facility that will deploy leading edge technology and pilot tools for sensor systems, packaging and associated flexible electronics platforms This Center is built upon and has been enabled by advances in the CHM.

The $25,000,000 Center for Advanced Roll-to-Roll Manufacturing is an open access facility that will deploy leading edge technology and pilot tools for sensor systems, packaging and associated flexible electronics platforms This Center is built upon and has been enabled by advances in the CHM.

Nanoinformatics Workshop 2015

The National Nanomanufacturing Network (NNN) coordinated a workshop convening participants from industry, academia and government to highlight advancements and opportunities of informatics in nanomanufacturing, EHS, materials design, engineering and fundamental science. This workshop helped to identify compelling nanotech data and tools, factors that make data useful and searchable, strategies for sharing data and future objectives. Conference website and proceedings: http://nanoinformatics.org/

The National Nanomanufacturing Network (NNN) coordinated a workshop convening participants from industry, academia and government to highlight advancements and opportunities of informatics in nanomanufacturing, EHS, materials design, engineering and fundamental science. This workshop helped to identify compelling nanotech data and tools, factors that make data useful and searchable, strategies for sharing data and future objectives. Conference website and proceedings: http://nanoinformatics.org/

Nanotechnology Training for K-12 Science Teachers at the NSEC Center for Hierarchical Manufacturing

The CHM conducted its eighth annual Nanotechnology Summer Institute for K-12 science teachers at UMass Amherst, July 7-11, 2014. Twenty five teachers learned from an array of nanotechnology curriculum modules with many hands-on activities for the classroom, including module on self-assembly, constructing an model atomic for microscope, creating a nanofilm, and more. Curriculum freely available at: http://www.umassk12.net/nano/

The CHM conducted its eighth annual Nanotechnology Summer Institute for K-12 science teachers at UMass Amherst, July 7-11, 2014. Twenty five teachers learned from an array of nanotechnology curriculum modules with many hands-on activities for the classroom, including module on self-assembly, constructing an model atomic for microscope, creating a nanofilm, and more. Curriculum freely available at: http://www.umassk12.net/nano/

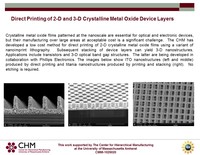

Direct Printing of 2-D and 3-D Crystalline Metal Oxide Device Layers

Crystalline metal oxide films patterned at the nanoscale are essential for optical and electronic devices, but their manufacturing over large areas at acceptable cost is a significant challenge. The CHM has developed a low cost method for direct printing of 2-D crystalline metal oxide films using a variant of nanoimprint lithography. Subsequent stacking of device layers can yield 3-D nanostructures. Applications include transistors and 3-D optical band gap structures. The latter are being developed in collaboration with Phillips Electronics. The images below show ITO nanostructures (left and middle) produced by direct printing and titania nanostructures produced by printing and stacking (right). No etching is required.

Crystalline metal oxide films patterned at the nanoscale are essential for optical and electronic devices, but their manufacturing over large areas at acceptable cost is a significant challenge. The CHM has developed a low cost method for direct printing of 2-D crystalline metal oxide films using a variant of nanoimprint lithography. Subsequent stacking of device layers can yield 3-D nanostructures. Applications include transistors and 3-D optical band gap structures. The latter are being developed in collaboration with Phillips Electronics. The images below show ITO nanostructures (left and middle) produced by direct printing and titania nanostructures produced by printing and stacking (right). No etching is required.

Fabrication of Flexible Microfluidic Chip using Nanoimprint Lithography

A CHM team has demonstrated a method to fabricate a flexible microfluidic chip using UV-assisted nanoimprint lithography containing electrowetting valves developed by Nugen and electrochemical transduction. The chip is designed to be amenable to a roll-to-roll manufacturing system. Microchannels were structured on a PET film. The electrodes were inkjet-printed on the flexible PET films. The figure below shows the functionalities of automated fluid delivery and actuation of the multivalve system with food dye in PBS buffer. Numerous applications include low cost patch sensors for biomarker detection in sweat, which is employed in an independent project funded by the DoD NanoBioManufacturing Consortium to assess stress and fatigue in the warfighter. The latter project is conducted in collaboration with GE and other partners.

A CHM team has demonstrated a method to fabricate a flexible microfluidic chip using UV-assisted nanoimprint lithography containing electrowetting valves developed by Nugen and electrochemical transduction. The chip is designed to be amenable to a roll-to-roll manufacturing system. Microchannels were structured on a PET film. The electrodes were inkjet-printed on the flexible PET films. The figure below shows the functionalities of automated fluid delivery and actuation of the multivalve system with food dye in PBS buffer. Numerous applications include low cost patch sensors for biomarker detection in sweat, which is employed in an independent project funded by the DoD NanoBioManufacturing Consortium to assess stress and fatigue in the warfighter. The latter project is conducted in collaboration with GE and other partners.

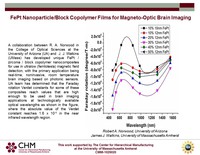

FePt Nanoparticle/Block Copolymer Films for Magneto-Optic Brain Imaging

A collaboration between R. A. Norwood in the College of Optical Sciences at the University of Arizona (UA) and J. J. Watkins (UMass) has developed unique FePt / zirconia / block copolymer nanocomposites for use in ultralow (femtotesla) magnetic field detection, with the primary application being real-time, noninvasive, room temperature brain imaging based on photonic sensors. UA team has determined that the Faraday rotation Verdet constants for some of these composites reach values that are high enough to be used in brain imaging applications at technologically available optical wavelengths as shown in the figure, where the absolute value of the Verdet constant reaches 1.6 x 10-6 in the near infrared wavelength region.

A collaboration between R. A. Norwood in the College of Optical Sciences at the University of Arizona (UA) and J. J. Watkins (UMass) has developed unique FePt / zirconia / block copolymer nanocomposites for use in ultralow (femtotesla) magnetic field detection, with the primary application being real-time, noninvasive, room temperature brain imaging based on photonic sensors. UA team has determined that the Faraday rotation Verdet constants for some of these composites reach values that are high enough to be used in brain imaging applications at technologically available optical wavelengths as shown in the figure, where the absolute value of the Verdet constant reaches 1.6 x 10-6 in the near infrared wavelength region.

CHM Factory of the Future Highlighted by Science Nation

Cost-effective, large area manufacturing of nanostructured materials lies at the heart of transforming substantial progress and investments in fundamental nanoscience and nanotechnology into products with significant economic and societal benefit. A recent video released by Science Nation describes the CHM efforts in roll-to-roll and solution based nanomanufacturing to meet this challenge.

Cost-effective, large area manufacturing of nanostructured materials lies at the heart of transforming substantial progress and investments in fundamental nanoscience and nanotechnology into products with significant economic and societal benefit. A recent video released by Science Nation describes the CHM efforts in roll-to-roll and solution based nanomanufacturing to meet this challenge.